United States 3D Printing Market Size, Growth & Report | 2033

Market Overview 2025-2033

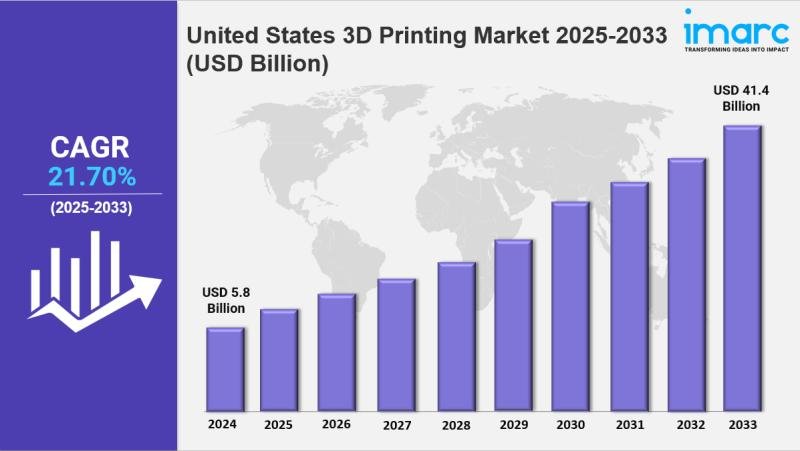

The United States 3D printing market size reached USD 5.8 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 41.4 Billion by 2033, exhibiting a growth rate (CAGR) of 21.70% during 2025-2033. The market is growing due to increasing demand for rapid prototyping, customized manufacturing, and supply chain efficiency. Growth is driven by technological advancements, government support, and expanding applications across industries, making the industry more dynamic, innovative, and competitive.

Key Market Highlights:

✔️ Strong market growth driven by advancements in additive manufacturing technologies

✔️ Increasing adoption across aerospace, healthcare, automotive, and consumer goods sectors

✔️ Expanding investments in R&D and industrial-scale 3D printing applications

Request for a sample copy of the report: https://www.imarcgroup.com/united-states-3d-printing-market/requestsample

United States 3D Printing Market Trends and Drivers:

The United States 3D Printing Market is seeing steady growth as more manufacturers turn to 3D printing to improve flexibility and reduce dependence on global supply chains. What used to be a niche technology is now playing a major role in how companies produce parts quickly and closer to home. In aerospace, for example, Boeing now uses 3D printing to create nearly a third of certain aircraft parts, cutting production time by more than half and wasting far less material in the process. The medical industry is also embracing 3D printing, with a 45% jump in FDA-approved printed devices in 2024 alone-especially for customized implants and surgical tools tailored to individual patients.

Carmakers like Ford are also getting in on the action, using metal 3D printing to make lighter parts that help improve fuel efficiency. With a shortage of skilled workers expected to reach 78,000 by 2026, national programs like America Makes are helping to train the next generation, ensuring the United States 3D Printing Market keeps moving forward. Materials are becoming more advanced too. High-performance alloys and newer photopolymers now make up nearly 70% of the market’s $2.1 billion materials segment, powering everything from jet engines to military components. Meanwhile, eco-friendly materials are catching on fast-like algae-based bioplastics, which more than doubled in use in 2024, partly thanks to stricter environmental rules in states like California.

3D printing is also heading to space. NASA is exploring ways to use moon dust (lunar regolith) for future construction projects on the Moon. Back here on Earth, startups like Fortify are pushing boundaries with carbon fiber 3D printing, backed by over $20 million in new funding. New materials are being developed faster, too, thanks to smarter digital tools that cut down research costs and testing time A growing trend in the United States 3D Printing Market is the shift toward on-demand production. Companies like Xometry and Protolabs are helping thousands of small and mid-sized businesses tap into 3D printing without needing to own the machines themselves.

This approach is making product development much more affordable-bringing prototype costs down from thousands of dollars to just a few hundred. Education is also helping drive long-term growth. Since 2024, most technical schools in the U.S. have added 3D printing programs, giving students hands-on experience with this evolving technology. Production is becoming more efficient, too. For example, Desktop Metal’s Live-Shop system lets manufacturers monitor machines remotely, cutting downtime by 70%. Security is a growing concern, especially in government-related projects. In response, investment in cybersecurity has tripled, and tools like blockchain are being used to protect sensitive 3D printing files and designs.

Design innovation is another big reason why the United States 3D Printing Market continues to grow. Generative design tools are making it possible to create much lighter parts-up to 80% lighter in some cases-without sacrificing strength Hybrid manufacturing, which combines 3D printing with traditional machining, is also gaining traction. Companies like DMG Mori are already seeing better profit margins by using this approach for precision parts. Standardization is making things easier, too. In 2024, organizations like ASTM and ISO introduced new qualification processes to help companies meet regulatory standards more easily.

Local production is also gaining popularity, with brands like Adidas using small-scale factories to produce shoes in just two days-cutting shipping emissions by nearly 90%. On the sustainability front, recycled titanium powder is now a more affordable and popular choice for many manufacturers. Looking ahead, the United States 3D Printing Market is set to benefit from even more innovation Technologies like digital twins, industrial IoT, and advanced simulations are expected to speed up material development and reduce printing errors significantly by 2027. With continued progress in design, education, sustainability, and production efficiency, 3D printing is becoming a key part of the future of American manufacturing.

Checkout Now: https://www.imarcgroup.com/checkout?id=3326&method=1190

United States 3D Printing Market Segmentation:

The report segments the market based on product type, distribution channel, and region:

Study Period:

Base Year: 2024

Historical Year: 2019-2024

Forecast Year: 2025-2033

Breakup by Component:

• Printer

o Desktop Printer

o Industrial Printer

• Material

o Polymers

o Metal and Alloys

o Ceramic

o Others

• Software

• Services

o 3D Scanning

o Designing

o Prototype Development

o Others

Breakup by Process:

• Binder Jetting

• Directed Energy Deposition

• Material Extrusion

• Material Jetting

• Powder Bed Fusion

• Sheet Lamination

• Others

Breakup by Technology:

• Stereolithography

• Selective Laser Sintering

• Electron Beam Melting

• Fused Deposition Modeling

• Laminated Object Manufacturing

• Others

Breakup by Application:

• Prototyping

• Tooling

• Functional Part Manufacturing

Breakup by Vertical:

• Consumer Products

• Industrial

• Aerospace and Defense

• Automotive

• Healthcare

• Education and Research

• Others

Breakup by Region:

• Northeast

• Midwest

• South

• West

Ask Analyst & Browse full report with TOC & List of Figures: https://www.imarcgroup.com/request?type=report&id=3326&flag=C

Competitive Landscape:

The market research report offers an in-depth analysis of the competitive landscape, covering market structure, key player positioning, top winning strategies, a competitive dashboard, and a company evaluation quadrant. Additionally, detailed profiles of all major companies are included.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Bitcoin

Bitcoin  Ethereum

Ethereum  XRP

XRP  Tether

Tether  Solana

Solana  USDC

USDC  Lido Staked Ether

Lido Staked Ether  TRON

TRON  Dogecoin

Dogecoin  Cardano

Cardano  Wrapped Bitcoin

Wrapped Bitcoin  Wrapped stETH

Wrapped stETH  Hyperliquid

Hyperliquid  Sui

Sui  Stellar

Stellar  Chainlink

Chainlink  Bitcoin Cash

Bitcoin Cash  Hedera

Hedera  Wrapped eETH

Wrapped eETH  Avalanche

Avalanche  Ethena USDe

Ethena USDe  Toncoin

Toncoin  LEO Token

LEO Token  Litecoin

Litecoin  WETH

WETH  USDS

USDS  Shiba Inu

Shiba Inu  Binance Bridged USDT (BNB Smart Chain)

Binance Bridged USDT (BNB Smart Chain)  Coinbase Wrapped BTC

Coinbase Wrapped BTC  WhiteBIT Coin

WhiteBIT Coin  Monero

Monero  Polkadot

Polkadot  Uniswap

Uniswap  Ethena Staked USDe

Ethena Staked USDe  Bitget Token

Bitget Token  Pepe

Pepe  Cronos

Cronos  Aave

Aave  Dai

Dai  Ethena

Ethena  Bittensor

Bittensor  Ethereum Classic

Ethereum Classic  NEAR Protocol

NEAR Protocol  Pi Network

Pi Network  Ondo

Ondo  OKB

OKB  Aptos

Aptos  Internet Computer

Internet Computer  Jito Staked SOL

Jito Staked SOL  BlackRock USD Institutional Digital Liquidity Fund

BlackRock USD Institutional Digital Liquidity Fund  Mantle

Mantle  USD1

USD1  Pudgy Penguins

Pudgy Penguins  Binance-Peg WETH

Binance-Peg WETH  Gate

Gate  Algorand

Algorand  Bonk

Bonk  VeChain

VeChain  Arbitrum

Arbitrum  Cosmos Hub

Cosmos Hub  Story

Story  Render

Render  POL (ex-MATIC)

POL (ex-MATIC)  sUSDS

sUSDS  Worldcoin

Worldcoin  Official Trump

Official Trump  Binance Staked SOL

Binance Staked SOL  Sky

Sky  Jupiter Perpetuals Liquidity Provider Token

Jupiter Perpetuals Liquidity Provider Token  Artificial Superintelligence Alliance

Artificial Superintelligence Alliance  Rocket Pool ETH

Rocket Pool ETH  Lombard Staked BTC

Lombard Staked BTC  Filecoin

Filecoin  Sei

Sei  SPX6900

SPX6900  USDtb

USDtb  Jupiter

Jupiter  USDT0

USDT0  KuCoin

KuCoin  StakeWise Staked ETH

StakeWise Staked ETH  NEXO

NEXO  Liquid Staked ETH

Liquid Staked ETH  Mantle Staked Ether

Mantle Staked Ether  Curve DAO

Curve DAO  Stacks

Stacks  Polygon Bridged USDT (Polygon)

Polygon Bridged USDT (Polygon)  Injective

Injective  Falcon USD

Falcon USD  Celestia

Celestia  Solv Protocol BTC

Solv Protocol BTC  Renzo Restaked ETH

Renzo Restaked ETH